Who we are

Firma ERG S.A. została założona w 1896 roku pod nazwą “Akcyjne Towarzystwo Elektryczność” z siedzibą w Warszawie i oddziałem produkcyjnym w Ząbkowicach. Przedmiotem jej działalności była produkcja wapna chlorowanego, sody kaustycznej i produktów węglowych. Sto lat później, czyli w roku 1996 ERG S.A. zmieniła swój profil produkcyjny i rozpoczęto produkcję folii polietylenowej metodą wytłaczania z rozdmuchem. W 2005 roku Spółka zadebiutowała na Giełdzie Papierów Wartościowych w Warszawie.

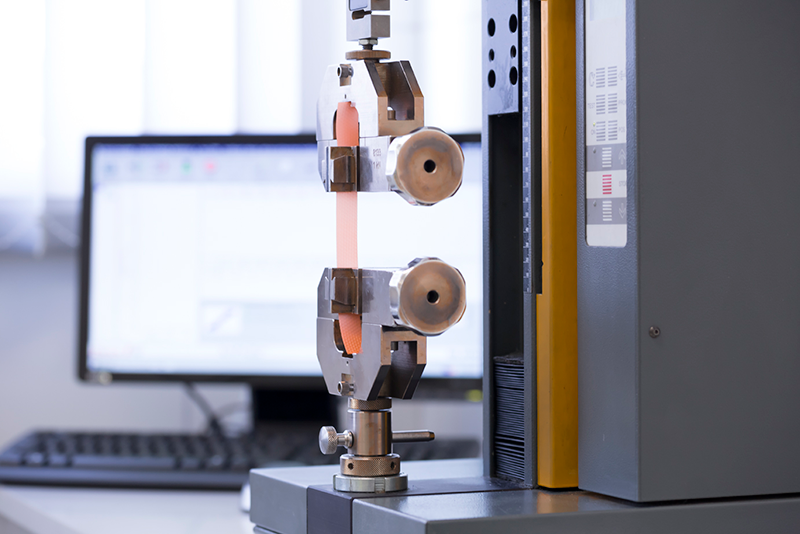

Firma posiada nowoczesny park maszynowy, który umożliwia produkcję około 17 tysięcy ton różnego rodzaju wysoko wyspecjalizowanych folii rocznie. Dzięki regularnym inwestycjom w technologię, utalentowanym pracownikom z wieloletnim doświadczeniem oraz konsekwentnej polityce kładącej nacisk na rozwój nowych produktów ERG S.A. dąży do osiągnięcia wiodącej pozycji w swojej branży nie tylko w Polsce, ale także w Europie.

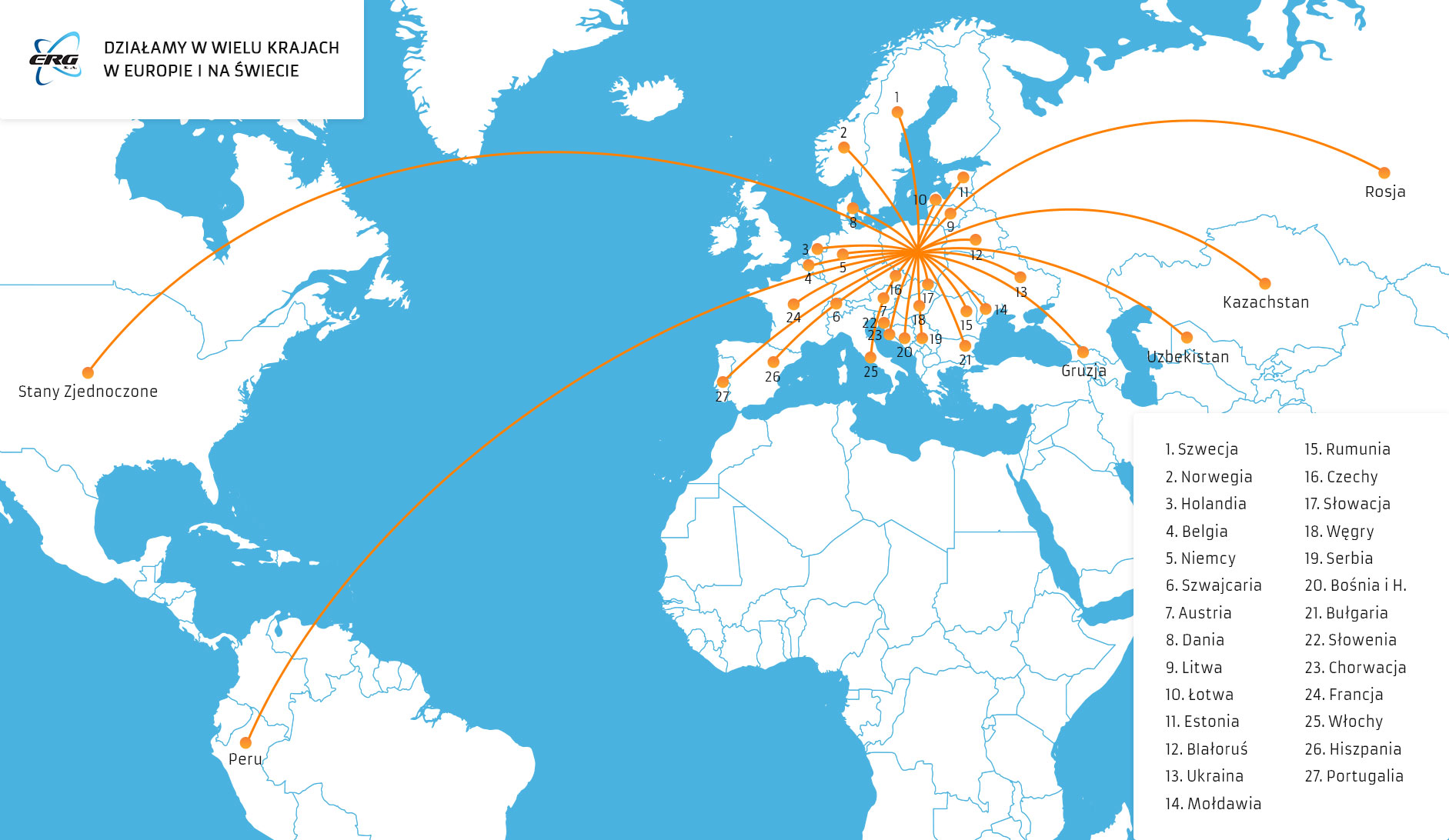

Polityka sprzedażowa ERG S.A. nie ogranicza się do rynku krajowego. Nasi kluczowi klienci są zlokalizowani głównie w Europie, ale także na pozostałych kontynentach. Eksport stanowi powyżej 20% całkowitej sprzedaży Firmy. Współpracujemy z międzynarodowymi korporacjami będącymi liderami branży przemysłowej, motoryzacyjnej, spożywczej, napojowej i poligraficznej.

Firma zatrudnia ponad 180 zmotywowanych pracowników, których część posiada ponad 25-letnie doświadczenie w branży, wykorzystywane na co dzień w wytwarzaniu wysokojakościowych produktów. Produkcja odbywa się nieustannie przez 24 godziny na dobę, 7 dni w tygodniu. Dzięki rygorystycznej analizie doboru surowców i całodobowej kontroli jakości wytwarzanych przez nas produktów, jesteśmy niezmiennie, wysoko oceniani przez partnerów handlowych. Korzystając z naszych umiejętności, doświadczenia, nowoczesnego parku maszynowego, potencjału rozwojowego i indywidualnego podejścia do klientów, jesteśmy nowoczesnym zakładem produkcyjnym, spełniającym najwyższe wymagania naszych klientów.

1896

Nasza historia sięga 1896 roku, kiedy to do życia została powołana Spółka “Akcyjne Towarzystwo Elektryczność” z siedzibą w Warszawie i fabryką w Ząbkowicach. Profil produkcyjny Zakładu to: wapno chlorowane, soda kaustyczna, węgle sztuczne.

1945 - 1949

Zmiana nazwy na Zakłady Elektrochemiczne „Ząbkowice”. Nacjonalizacja zakładu i rozpoczęcie produkcji, m.in. azydku sodu, sprężonego wodoru, chlorofenu, chlorku żelaza, oraz nadtlenku wodoru do zastosowań farmaceutycznych.

1972

Zmiana nazwy na Zakład Tworzyw Sztucznych „Erg-Ząbkowice”. Wprowadzenie produkcji z tworzyw sztucznych w miejsce zlikwidowanej produkcji nieorganicznej.

1996

Przekształcenie w Spółkę Akcyjną, emisja akcji dla osób uprawnionych.

Uruchomienie linii do produkcji folii termokurczliwych.

2000

Założenie zakładu recyklingu i granulowania tworzyw sztucznych zajmującego się przetwarzaniem odpadów z tworzyw sztucznych z własnej produkcji jak również skupowanych z sieci handlowych i zakładów produkcyjnych.

2005

Dopuszczenie akcji firmy do publicznego obrotu papierami wartościowymi oraz debiut na Warszawskiej Giełdzie Papierów Wartościowych.

2006

Uruchomienie nowoczesnej linii do produkcji trójwarstwowej folii LDPE metodą wytłaczania z rozdmuchem.

2007

Rozszerzenie Grupy Kapitałowej o „BIOERG”, będący prekursorem produkcji kompostowalnych opakowań z tworzyw sztucznych w Polsce.

2016

Wdrożenie i certyfikacja systemów ISO 22000: 2006 i ISO 9001: 2015. Sprzedaż spółki zależnej BIOERG.

2019

Gospodarowanie odpadem produkcyjnym w obiegu zamkniętym umożliwiającym jego ponowne wykorzystanie w 100%.

2020

Wykorzystanie nowej bazy surowców ze źródeł odnawialnych redukujących ślad węglowy do produkcji folii LDPE oraz HDPE przyjaznych dla środowiska naturalnego.